The mine galleries where they dig for ore look like metro tunnels, the only difference being that passengers on a train pass through a section of tunnel in a couple of minutes, while miners spend their whole working day in the dark and damp underground conditions. The small town of Gay in the Orenburg Region relies on ore mining for its livelihood: the town sprang up at the end of the 1950s around a unique ore deposit and now a third of its able-bodied population - 7,500 people - works here.

Roman Baikalov / Press photo

The town near the mine was founded by Ukrainians at the end of the 19th century – “Gay” in Ukrainian means "copse" and it was among birch trees that the first bore was drilled and it was decided to build a whole town centered on a single enterprise, the Gay Ore Processing Plant (GOK). It includes an underground mine, an open-pit mine, mine construction department offices, and a factory where mined raw material is crushed and separated from impurities. Copper, zinc, gold, and silver are obtained from the local ore. But the miners work with the ore in its original form, so the future metals look like a pile of dust-covered dark grey rocks.

Miners' tracking devices

Roman Baikalov / Press photo

The working shift of a miner lasts about seven hours and begins in the changing room. Workwear includes cotton underwear, woolen socks, a jacket, a pair of trousers, high rubber boots, and a helmet, of course. In a special room - the lamp room - miners get a helmet lamp and a self rescuer device. In an emergency, this metal container with a lid will provide a supply of oxygen: inside is a bag with a reagent that processes carbon dioxide, a clip for the nose, and a tube through which to inhale and exhale. "At normal walking pace, the self rescuer will last for 60 minutes. The main thing is not to panic," they advise you at the induction course. But, it seems, it’s more important to be able to open the extremely tight lid in the first place.

Roman Baikalov / Press photo

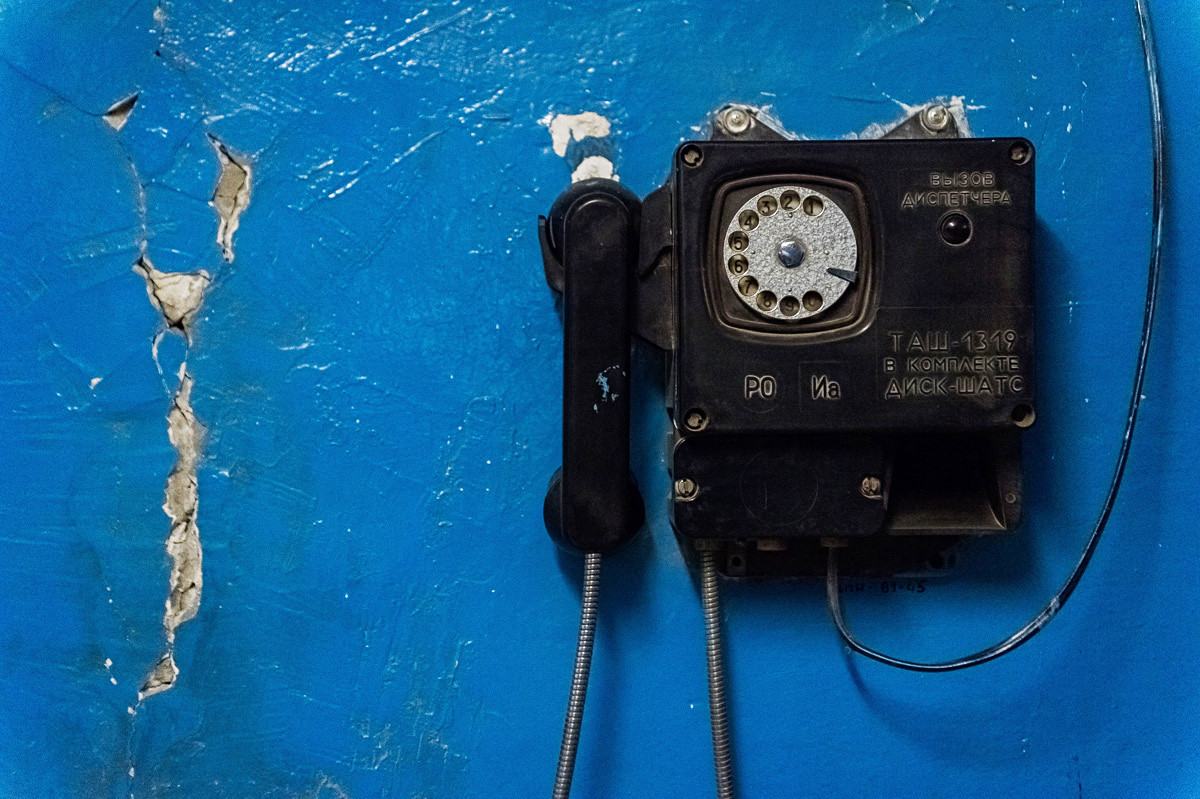

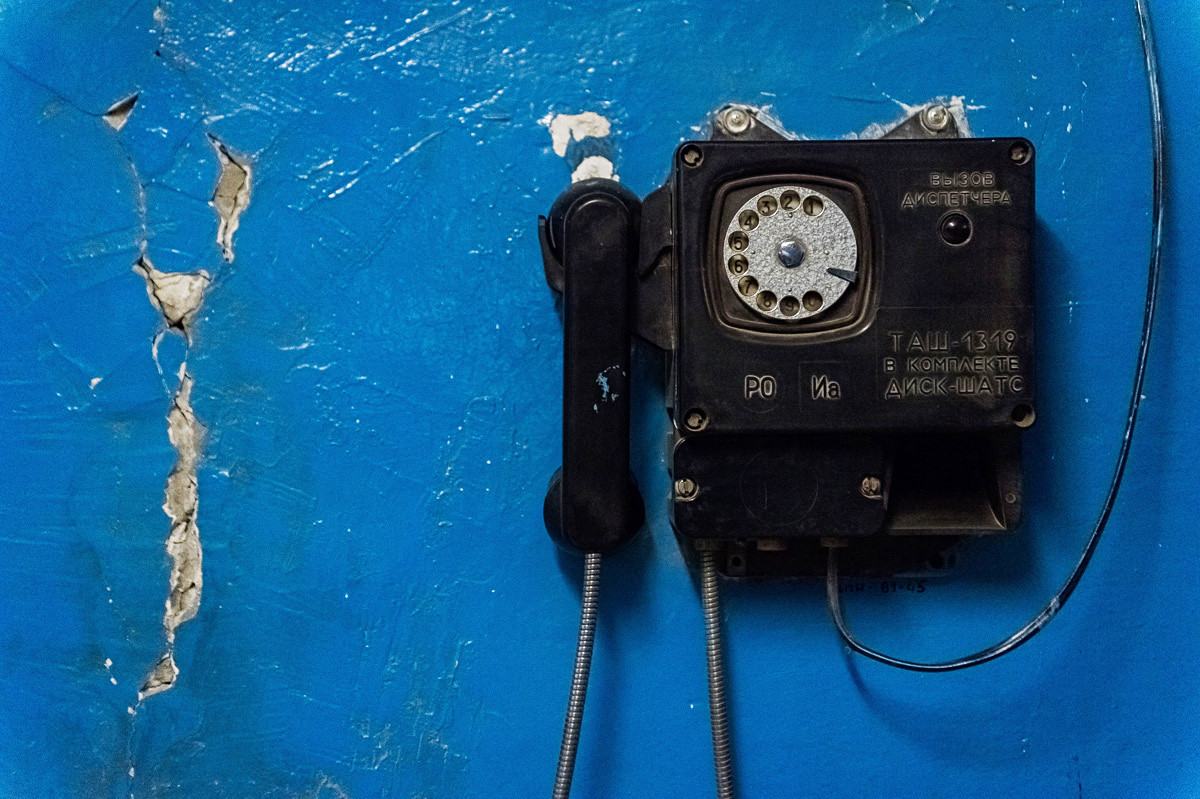

Having fastened the lamp to your helmet, you learn not to look your fellow miner in the eyes to avoid dazzling them. It is the lamp that holds the key to being rescued in the event of danger. A personalized sensor is installed inside it, enabling a dispatcher to monitor a miner’s location in real time and to know where to send a rescue party. A whole system of signals has been invented for communication with the above-ground support services. For example, if a miner's lamp blinks twice, it means wants to get in touch with the operator above ground. For that, there are landline telephones underground.

Underground traffic lights

Roman Baikalov / Press photo

The Gay GOK mine is the deepest copper ore mine in Europe. Mining is carried out at a depth of 1,075 meters. The miners descend to the right level in a cage - a large lift without doors. It moves at eight meters a second and gradually decelerates when approaching the right "floor." Finally, you find yourself in a labyrinth of dimly-lit passages and, squelching in the mud on the way to the mine utility vehicle, and realize why you needed to put on rubber boots.

Roman Baikalov / Press photo

The journey around the mine is neither fast nor straight: the 220 km of underground passageways have about a 1000 crossroads. As in normal life, the movement of equipment here is regulated with the help of traffic lights. "They operate automatically, reacting to ultrasound emitted by the sensors in the miners' lamps," explains Vladislav Savelyev, the chief power engineer of the underground mine. "When the light is red, the driver, as a rule, drives into a turning niche and lets the oncoming vehicle pass."

Roman Baikalov / Press photo

For the repair of mining equipment and its maintenance, the mine has its own car wash and service center at the 990-meter level. On the same level, the miners have a small cave-like dining area: Right under the roof of the mine stands a long table with two benches, a microwave and crudely made metal lockers for personal belongings. The miners bring their own food, known as tormozok.

Not a job for women

Roman Baikalov / Press photo

According to preliminary calculations, ore reserves at the Gay deposit should last for at least 40 years. Mining takes place in several stages: First, holes are drilled in the rock, and then charges are put in them and detonated. Then the mined rock is collected in a load-haul-dump machine that looks like a long and low excavator. It carries the raw material to the receiving hopper, from which the ore enters the conveyor, which takes it up, or, as the miners say: “to the top.”

Roman Baikalov / Press photo

On each shift about 500 people go underground. Most of them are men. This is because since 1974 women have been barred from a list of professions on the grounds of difficult working conditions and workplace hazards. Physical work underground is among the professions at the top of the list, so you won't find women among the miners. Still, there are women at the mine: For example, they work at a warehouse 685 meters below ground, dispensing explosives.

Roman Baikalov / Press photo

"I suppose you could call me the adventurous type. When four years ago they offered me a job underground, I agreed out of curiosity, if nothing else", says Tatiana Bayeva. "In our warehouse everything is automated, there are loaders, so the job is not as hard as the men’s; still it is a big warehouse and, since you are running around all day, there is never time to get cold". But the underground "tourists" already feel cold after their two-hour visit: After a chilly +14 degrees you do want to go somewhere warm - it must be for this reason that the changing rooms have bathrooms and a heated floor.

Brilliant workers

Roman Baikalov / Press photo

The miner's shift ends at the plant's entrance gate. There is a screen installed there on which the day's output of every miner is displayed. The miners work in groups, or teams, and there is an unspoken competition among them: Who will exceed the target by the largest amount? The overall target is to increase ore mining from 8 to 9 million tonnes a year by 2021. The best workers are known here by the name of their team leader - the Khristoforov team or the Letov team. This tradition is somewhat reminiscent of Soviet times when newspapers often wrote about such heroic performance at work.

Roman Baikalov / Press photo

Nowadays such topics are covered less often in the media or mass culture but, as the miners themselves say, such competition motivates them a lot. The Gay mine provides raw material to one of the biggest copper holding companies, the Ural Mining and Metallurgical Company, and, as far as ore mining in Russia is concerned, ranks second only to a similar plant in Norilsk. But it’s not just about a desire to be first, and not even the miner's salary, which is considered quite high in the region and depends on performance. "For most people, working here is a conscious decision: They are following in the footsteps of their parents," says Aleksandr Mikhin, deputy director in charge of general issues. "In every family you will find a person linked to the company. There are no random people at the mine.

Roman Baikalov / Press photo

The job of a miner may have lost its romantic appeal in the popular imagination, but for the miners themselves it is full of high meaning and, to some extent, a tribute to the memory of their ancestors.

Roman Baikalov / Press photo

If using any of Russia Beyond's content, partly or in full, always provide an active hyperlink to the original material.